Automatic snack food packaging machine Automatic vertical granular packing machine

1. Description

This automatic multi-function packing machine is a new generation of

high-tech products, which combines with domestic and foreign most advanced

packing structural features and fully automatic control system. It can automatically

weigh, fill, wrap, print the date and batch number, seal, labeling, cut off,

count and convey.

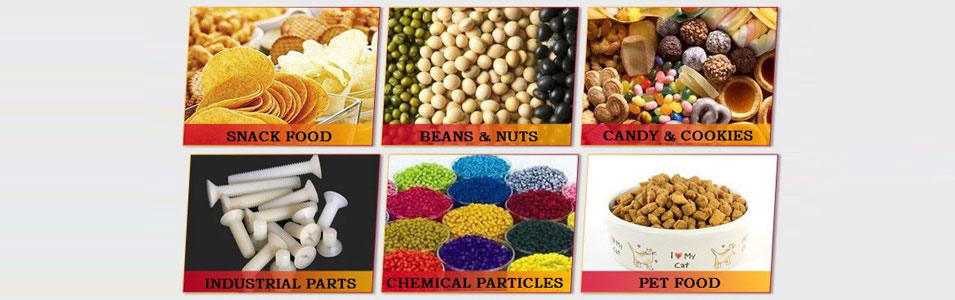

2. Application

This machine is widely used in food, medicine, agriculture and many other

industries and suitable for various kinds of solid products. It can

be used in the packaging of all kinds of grain material, sheet material and

abnormity material, such as candy, melon seeds, chips, peanuts, preserved

fruit, jelly, confect, pet food, dilatant foodstuff and so on.

3. Basic Parameters

|

Power

|

3.5 kW

|

Net Weight

|

650 kg

|

|

Certification

|

CE, ISO 9001

|

Voltage

|

220 V or customer

required

|

|

Packing Range

|

50-5000 g

|

Bag Size

|

Width:60-210 mm, Length:50-300 mm

|

|

Condition

|

New

|

Packing Speed

|

20-40 bags/min

|

|

Warranty Time

|

12 months

|

Dimension

|

2100*2500*3500 mm

|

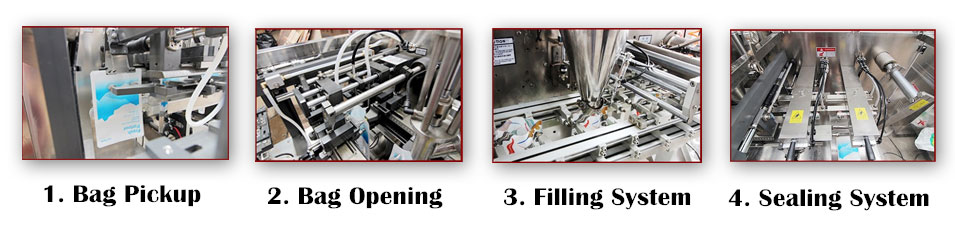

4. Details

-

Bag Pickup: Pneumatic sucking system ensure the bags being picked up automatically.

-

Bag Opening: A strong bag holding and sucking system for bags being opened in stable condition.

-

Filling System: Continious working station of bag transfering to be filled with products.

-

Sealing System: Sophisticated sealing structure for premade bag (with zipper or without) in reliable sealing.

5. Features

-

Adopt industrial PLC control system, ensure the stable performance and be easy for parameters adjusting.

-

Adopt the most advanced microcomputer chip control system.

-

High precision data-type weighing sensor realizes precise weighing.

-

Separate PID temperature controller, suitable for the sealing of various packing materials.

-

Memory storage function of twenty sets parameters for different product package change.

-

Muilti-union roll film structure and sophisticated sealing framework for perfect bag shape forming.

-

Different kinds of weighers are available for choice to meet various products packing in a wide range of weight.

-

High quality spare parts from World-famous Brand igus, Leadshine, SMC and SIEMENS,ensure the stability, longer working life and easy to get for replacing.

6. Q & A

Q1. How to find a packing machine that suits my product?

Re: Tell us about your

product details and the packing requirements.

(1) What kind of product you

have.

(2) The bag/pouch size (length

and width).

(3) The weight of your product

for each bag (it depends on what specific

product you have).

(4) Your requirement for the

machines and the bag types.

Q2. Can your company do ODM for

the packing machine?

Re: Yes. We have a

strong engineering team which can make designs for non-standard machines

to meet different needs of a package solution.

Q3. How can I check the machine quality after placing an order?

Re: Before delivery, We will

do testing on every machine and send the testing video and pictures for your

check. And also you can arrange for quality checking by the third-party

inspection organization.

Q4. How can deal with the machine if it has a problem on my site?

Re: We have full-time staff

to service you. The after-sales team with technicians will help to find out the

problem and give advice to you. If need oversea service, we have

professional technicians with oversea service experience to serve oversea

clients. But service charges and travel fee with accommodation are

responsible for your side.

Q5. We are afraid you won't send us machines after payment?

Re: Please note our above business

license and certificate from the government agency. We are the partner of world's largest popcorn supplier----Pop Weaver, this is the witness of our strength! And if you don't trust us,

then we can use trade assurance service or payment by L/C to guarantee your

money.

Q6. Can you explain the whole transaction process?

Re: (1) Sign the contract.

(2) Arrange a 30% deposit to us.

(3) Workshop arranges production.

(4) Testing and detecting the machine before shipment.

(5) Arrange the balance before shipment.

Q7. What is your after-sales services?

Re: Manual Installation Book, Video Support,

Online Support. And if need oversea service, we will send professional

technicians with oversea service experience to serve oversea clients. But

service charges and travel fee with accommodation are responsible for your

side.

Q8. Why we should choose your company?

Re: High quality spare parts from the world

famous ABB and SIEMENS,

ensure stable safe operation, longer working life and easy to get for

replacements.

Q9. What’s the differences for solid, powder or

liquid packing?

Re: For liquid, we advise piston or

motor pump, for powders, we advise auger filler or volumetric cup filler, for

solid, granule and flack, we advise multi-head weigher, linear weigher or

volumetric cup filler.